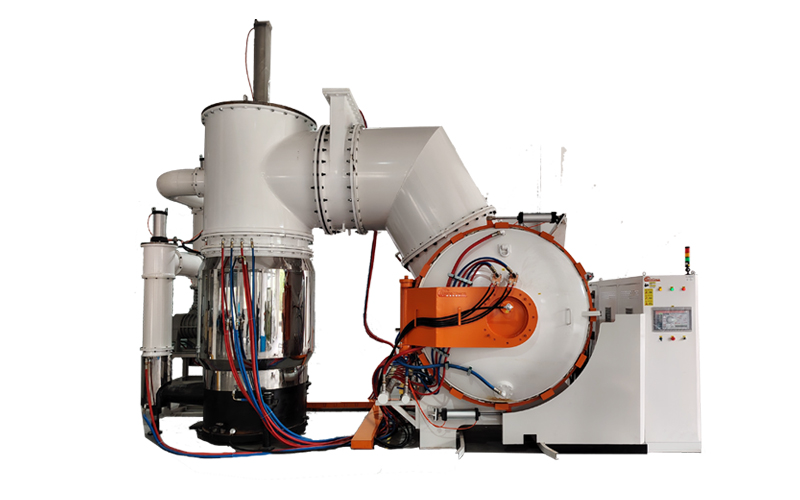

Vacuum and Protective Gas Melting Furnace

- 2025-08-07 21:27

- Brother Furnace

This Vacuum and Protective Gas Melting Furnace employs medium frequency induction heating within a rigorously controlled atmosphere environment. It is specifically engineered to perform metal melting operations under either high vacuum conditions or various protective gas atmospheres (such as argon or nitrogen).

This capability is crucial for processing materials that are sensitive to oxidation and contamination. The furnace finds widespread application in both research and production settings for advanced materials, including:

Nickel-based superalloys

Specialty steels

Precision alloys

Reactive and refractory metals (e.g., Titanium, Zirconium)

High-temperature alloys

Magnetic materials

It is particularly suited for the precision casting of small components where exceptional material purity and controlled solidification are paramount.

Vacuum and Protective Gas Melting Furnace Technical Parameters

| Model | Capability(KG) | Rated Frequency(HZ) | Power(KW) | Max. Vacuum (Pa) | Cooling Water (T/H) |

|---|---|---|---|---|---|

BR-RLL-10 | 10 | 3000 | 60 | 7x10-3 Pa | 10 |

BR-RLL-25 | 25 | 2500 | 120 | 7x10-3 Pa | 15 |

BR-RLL-50 | 50 | 2000 | 160 | 7x10-3 Pa | 25 |

BR-RLL-100 | 100 | 2000 | 200 | 7x10-3 Pa | 30 |

BR-RLL-200 | 200 | 1000 | 200 | 7x10-3 Pa | 35 |

BR-RLL-300 | 300 | 800 | 250 | 7x10-3 Pa | 40 |

BR-RLL-500 | 500 | 800 | 350 | 7x10-3 Pa | 50 |

BR-RLL-1000 | 1000 | 800 | 400 | 7x10-3 Pa | 70 |

* Other size can be customized.