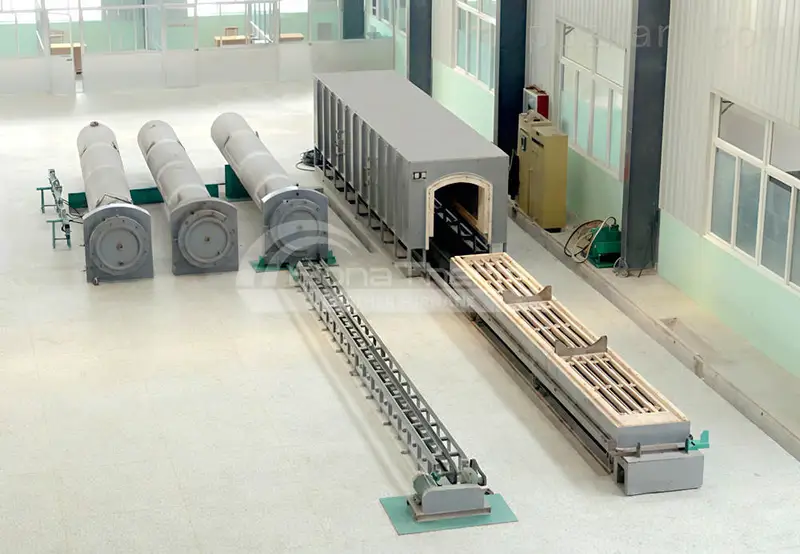

This Industrial Vacuum Annealing Furnace is designed specifically for vacuum annealing of copper tubes. It enhances crystalline structure, delivers a bright surface finish, improves degassing efficiency, and significantly boosts overall material performance.

Copper Tubes Annealing Furnace Features

- Elimination of work hardening: Restores plasticity after cold processing for easier subsequent forming.

- Optimized grain structure: Homogenizes microstructure to enhance mechanical properties.

- Oxidation prevention: Vacuum annealing eliminates surface discoloration.

- Hydrogen embrittlement mitigation: Avoids brittleness risks from hydrogen in traditional atmosphere annealing.

- Integrated structure: Lightweight, high-purity alumina furnace chamber ensures safety and environmental compliance.

- Uniform heating: High-quality resistance wires ensure consistent temperature distribution.

- Full automation: Pre-set programs enable automatic heating/cooling cycles.

- User-friendly interface: Power and heating indicators for real-time monitoring.

Copper Tubes Annealing Furnace Applications

- Power industry: Cables, transformers

- Refrigeration: Condenser tubes (ACs, refrigerators)

- Electronics: Heat sinks, connectors

- Aerospace: High-precision conduits

- New energy: Solar panels, battery components

Technical Specifications

- Dimensions: φ360×6400mm (Diameter × Depth)

- Temperature: Max 900°C, standard 850°C (±1°C or ±5°C accuracy)

- Power: 380V, 3-phase, 50Hz, 248.2 kW

- Control system:

- 10-inch LCD touchscreen with 30 programmable curves, 30-day data storage, USB export

- Siemens PLC automation, bidirectional anti-parallel thyristor voltage regulation

- Self-tuning temperature control, vacuum system integrated into touchscreen

- Heating elements: OCr25Al5 resistance wire with high tensile strength and oxidation resistance.

- Furnace structure:

- Double-layered chambers (outer: 309s stainless steel, δ8; inner: 321 stainless steel, δ5)

- Robust steel frame, mobile furnace body with 5-7m/min drive system

- 50mm I-beam rails, modular cooling ducts, and air vents

- Atmosphere protection: N₂ atmosphere with auto-purging and pressure alarms.

- Vacuum system:

- 2X-70 rotary vane pump + 2X-70 mechanical pump

- Valves controlled by cylinders and pneumatic solenoid valves

- Ventilation: 304 stainless steel ventilation tube at rack base, compressed air backflushing at furnace mouth.

- Safety systems: Over-temperature, thermocouple break, and pressure alarms with automatic shutdown.

Contact us now for the best quote!