The BR-QHS series Vacuum Brazing Furnace for Aluminum incorporates multiple advanced proprietary technologies, supporting one-touch automatic control or manual operation. It features automatic safety interlock protection, fault self-diagnosis, and alarm functions.

This furnace rapidly heats up under high vacuum to achieve an exceptionally uniform temperature, offering high precision, fast response, excellent reliability, strong anti-interference capability, long service life, and superior dynamic performance. It is also user-friendly, easy to operate and maintain, and features an aesthetically pleasing design.

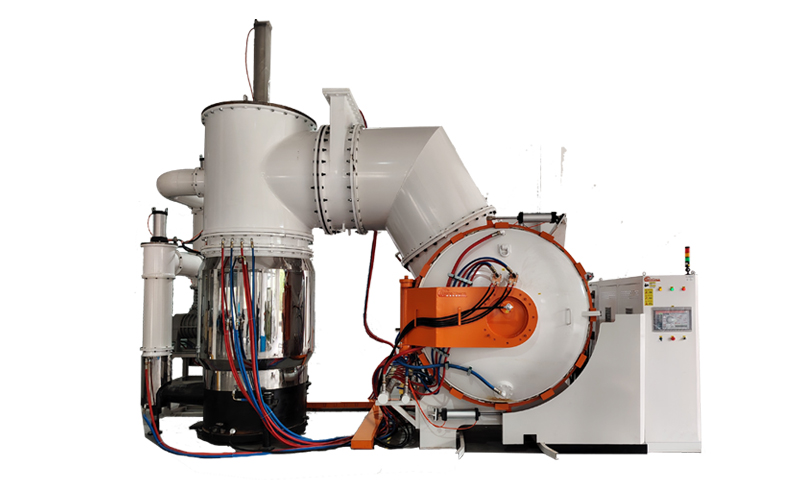

Furnace Structure

Consists of the main unit, vacuum system, gas charging system, electrical control system, and water cooling system.

Furnace Body Design

The main unit adopts a horizontal single-chamber structure, comprising the furnace body, furnace door, and heating chamber.

The furnace body and door are of double-wall water-cooled construction, with a gap between the two layers for coolant circulation.

The front end connects to the furnace port flange, while the rear end connects to the end plate.

The lower part of the furnace body is equipped with support brackets.

The furnace body includes the following openings:

- Vacuum pumping ports

- Electrode feedthroughs

- Temperature control ports

- Temperature measurement ports

- Other auxiliary ports

Heating Zone

● The heating chamber is a cylindrical structure made of stainless steel, consisting of heating elements, metal thermal insulation shields, workpiece trays, insulating ceramic bases, and workpiece support mechanisms.

● The entire heating chamber can be removed as a single integrated unit for easy maintenance and repair.

Heating System

The heating system employs a closed-loop control system consisting of thermocouples, temperature controllers, thyristor voltage regulators, and heaters, ensuring high temperature control accuracy and excellent responsiveness of the furnace.

Electrical Control System

Real-time control of the furnace's temperature, vacuum, gas circuits, and mechanical actions is achieved through configuration buttons on the touch screen.

The operating system is easy to learn and use, featuring a user-friendly graphical human-machine interface (HMI) that dynamically displays the process flow and operational status in real time.

It offers massive storage capacity with significant expansion potential, multiple operation permission levels, each protected by password security.

Temperature Control Instrument: Eurotherm industrial PID signal controller.

Vacuum System

Customizable based on configuration.

The vacuum system incorporates a self-protection logic interlock system to prevent operational errors.

Cooling Tower (To be provided by the customer or procured by us)

External Loading Cart (To be provided by the customer or procured by us)

Main Specification

| Temperature Control | 15-inch touch screen for fully automatic control |

| Heating Zone | Customizable |

| Continuous Working Temp. | ≤700 ℃ |

| Temperature Control Zones | Customizable |

| Heating Rate | Adjustable, 0–20℃/min |

| Temperature Control Accuracy | ≤± 1℃ |

| Heating Elements & Furnace Chamber | Metal heating strip + high-purity stainless steel |

| Max. Vacuum | 5 × 10⁻⁴ Pa |

Aluminum Brazing Vacuum Furnace Standard Size:

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-QHS-223 | 200*200*300mm | 750℃ | 12kW | 380V | 5×10-4 Pa |

| BR-QHS-334 | 300*300*400mm | 750℃ | 21kW | 380V | |

| BR-QHS-446 | 400*400*600mm | 750℃ | 34kW | 380V | |

| BR-QHS-557 | 500*500*700mm | 750℃ | 46kW | 380V | |

| BR-QHS-669 | 600*600*900mm | 750℃ | 64kW | 380V |

*Other sizes can be customized