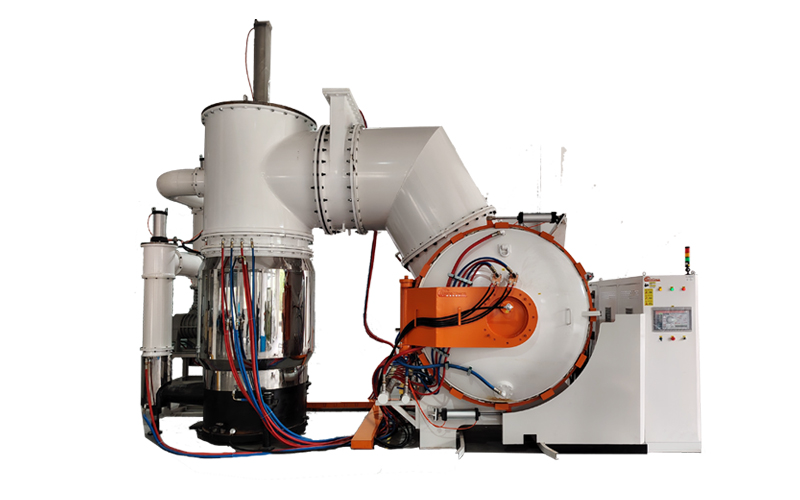

Vacuum Quenching and Tempering Furnace for HR coils & sheets

- 2025-06-24 23:46

- Brother Furnace

Our advanced Vacuum Quenching and Tempering Furnace, engineered specifically for processing HR coils & sheets, is now factory-tested and prepared for immediate dispatch. This system delivers exceptional thermal uniformity at extreme temperatures up to 1350°C, precision-optimized for distortion-critical quenching and stress-relieving tempering of high-carbon/low-alloy steel coils and plates.

Featuring ±1°C temperature accuracy and a high-integrity vacuum-sealed chamber, it guarantees decarburization-free hardening, oxidation suppression, and repeatable microstructure refinement. The integrated quench system and multi-zone tempering control ensure uniform mechanical properties across full-width coils and thick-plate sections.

Vacuum Quenching and Tempering Furnace for HR coils & sheets Features

- The Chamber size is 500x500x700mm (WxHxD)

- The heating chamber is composed of graphite heater graphite soft felt and hard felt, the max operation temperature is 1350℃.

- The multiserial graphite spray nozzle is located inside the heating chamber along with the induction inwall. The gas uniform was sprayed from the spray nozzle during gas quenching.

- The material platform is composed of graphite support, a hearth, and an Al203 sticker. This structure will prevent the adhesion between the platform and the hearth during high temperatures.

- The heat field can also use high-temperature molybdenum belt heating, and molybdenum foil heat shield furnace. The heat field has no volatilization, no impurities, and no pollution to the heat treatment workpiece.

- Gas cooling system: which is composed of a high press wheel blower, multistage high-efficient copper heat exchanger, and duct deflector. Filling high purity N2 or Arduring gas cooling, spray to workpiece through duct deflector to achieve workpiece uniform cooling.

- The gas cooling pressure is adjustable from 1-10bar.

- Max cooling rate: from 1150℃ to 250℃ less than 7min. (The cooling water temperature is lower than 35 ℃)

Vacuum Quenching and Tempering Furnace for HR coils & sheets Parameters

Model | Chamber Size (W*H*D)mm | Max. Temp (℃) | Heating Elements | Capacity (KG) | Power(KW) | Max. Vacuum (Pa) |

|---|---|---|---|---|---|---|

BR-QCL-334G | 300*300*450 | 1350 | Graphite | 100 | 50 | 7x10-1 Pa |

BR-QCL-446G | 400*400*600 | 1350 | Graphite | 200 | 80 | 7x10-1 Pa |

BR-QCL-557G | 500*500*700 | 1350 | Graphite | 300 | 120 | 7x10-1 Pa |

BR-QCL-669G | 600*600*900 | 1350 | Graphite | 500 | 150 | 7x10-1 Pa |

BR-QCL-8812G | 800*800*1200 | 1350 | Graphite | 900 | 260 | 7x10-1 Pa |

Model | Chamber Size (W*H*D)mm | Max. Temp (℃) | Heating Elements | Capacity (KG) | Power(KW) | Max. Vacuum (Pa) |

|---|---|---|---|---|---|---|

BR-QCL-334G | 300*300*450 | 1350 | Molybdenum | 100 | 50 | 7x10-1 Pa |

BR-QCL-446G | 400*400*600 | 1350 | Molybdenum | 200 | 80 | 7x10-1 Pa |

BR-QCL-557G | 500*500*700 | 1350 | Molybdenum | 300 | 120 | 7x10-1 Pa |

BR-QCL-669G | 600*600*900 | 1350 | Molybdenum | 500 | 150 | 7x10-1 Pa |

BR-QCL-8812G | 800*800*1200 | 1350 | Molybdenum | 900 | 260 | 7x10-1 Pa |

* Other sizes can be customized.