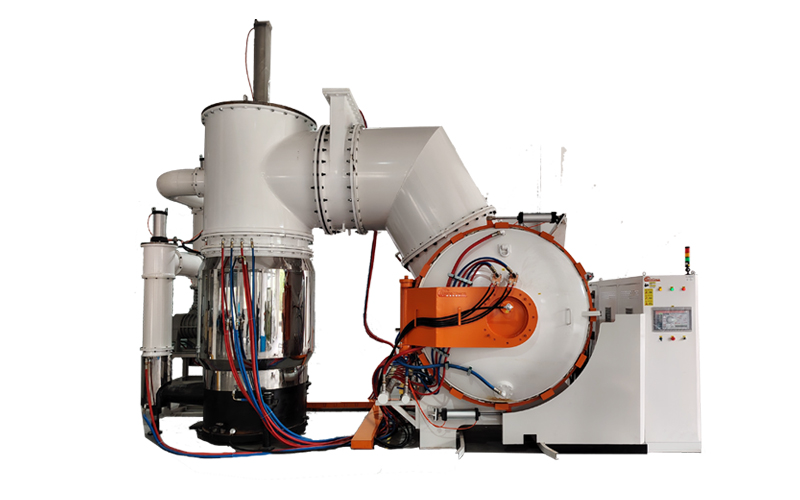

Vacuum Heat Treat Quenching Furnace for High Speed Steel

- 2025-12-18 22:34

- Brother Furnace

We are pleased to announce the successful completion of Factory Acceptance Testing (FAT) for our latest Vacuum Heat Treat Quenching Furnace for High Speed Steel. This advanced system is exceptionally engineered to meet the exacting demands of high-speed steel (HSS) tool and component manufacturing.

This furnace guarantees the critical, decarburization-free hardening essential for HSS by maintaining a high-vacuum sealed environment throughout the process. It achieves outstanding thermal uniformity at extreme temperatures up to 1350°C, fully covering the austenitizing range of all commercial HSS grades (e.g., M2, M42, T1).

Vacuum Heat Treat Quenching Furnace for High Speed Steel Features

- The Chamber size is 500x500x700mm (WxHxD)

- The heating chamber is composed of graphite heater graphite soft felt and hard felt, the max operation temperature is 1350℃.

- The multiserial graphite spray nozzle is located inside the heating chamber along with the induction inwall. The gas uniform was sprayed from the spray nozzle during gas quenching.

- The material platform is composed of graphite support, a hearth, and an Al203 sticker. This structure will prevent the adhesion between the platform and the hearth during high temperatures.

- The heat field can also use high-temperature molybdenum belt heating, and molybdenum foil heat shield furnace. The heat field has no volatilization, no impurities, and no pollution to the heat treatment workpiece.

- Gas cooling system: which is composed of a high press wheel blower, multistage high-efficient copper heat exchanger, and duct deflector. Filling high purity N2 or Arduring gas cooling, spray to workpiece through duct deflector to achieve workpiece uniform cooling.

- The gas cooling pressure is adjustable from 1-10bar.

- Max cooling rate: from 1150℃ to 250℃ less than 7min. (The cooling water temperature is lower than 35 ℃)

Vacuum Heating Quenching Furnace Parameters

Model | Chamber Size (W*H*D)mm | Max. Temp (℃) | Heating Elements | Capacity (KG) | Power(KW) | Max. Vacuum (Pa) |

|---|---|---|---|---|---|---|

BR-QCL-334G | 300*300*450 | 1350 | Graphite | 100 | 50 | 7x10-1 Pa |

BR-QCL-446G | 400*400*600 | 1350 | Graphite | 200 | 80 | 7x10-1 Pa |

BR-QCL-557G | 500*500*700 | 1350 | Graphite | 300 | 120 | 7x10-1 Pa |

BR-QCL-669G | 600*600*900 | 1350 | Graphite | 500 | 150 | 7x10-1 Pa |

BR-QCL-8812G | 800*800*1200 | 1350 | Graphite | 900 | 260 | 7x10-1 Pa |

Model | Chamber Size (W*H*D)mm | Max. Temp (℃) | Heating Elements | Capacity (KG) | Power(KW) | Max. Vacuum (Pa) |

|---|---|---|---|---|---|---|

BR-QCL-334G | 300*300*450 | 1350 | Molybdenum | 100 | 50 | 7x10-1 Pa |

BR-QCL-446G | 400*400*600 | 1350 | Molybdenum | 200 | 80 | 7x10-1 Pa |

BR-QCL-557G | 500*500*700 | 1350 | Molybdenum | 300 | 120 | 7x10-1 Pa |

BR-QCL-669G | 600*600*900 | 1350 | Molybdenum | 500 | 150 | 7x10-1 Pa |

BR-QCL-8812G | 800*800*1200 | 1350 | Molybdenum | 900 | 260 | 7x10-1 Pa |

* Other sizes can be customized.