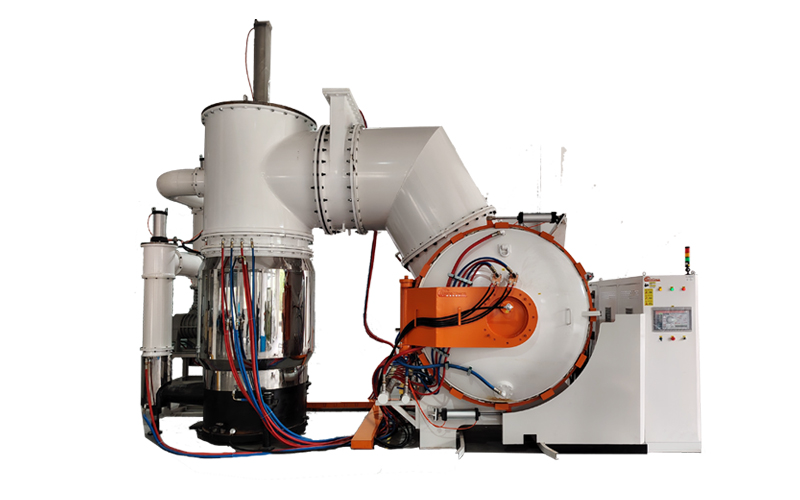

Vacuum Brazing Equipment for Diamond Tools

- 2025-06-05 00:33

- Brother Furnace

Our Vacuum Brazing Equipment for Diamond Tools delivers superior high-temperature stability reaching 1350°C, engineered for precision joining of superhard materials. Featuring uniform thermal control (±5°C) and vacuum-sealed chamber technology, it ensures oxidation-free bonds for diamond tooling, carbide components, wear parts, and high-performance alloys. The heavy-duty insulation system and intelligent process automation meet rigorous demands in aerospace, energy, and precision manufacturing sectors. Units are warehouse-stocked and ready for expedited global shipment, minimizing lead times for critical brazing applications.

Vacuum Brazing Equipment Features

- Using molybdenum foil metal furnace chamber, and molybdenum belt for heating element, the highest temperature can reach 1350℃.

- Chamber size: 400x400x600mm(WxHxD)

- Molybdenum heating belts are distributed circularly in the furnace chamber, the surrounding radiation heating, the furnace chamber temperature uniformity is high, up to ±5℃.

- Clean stainless steel furnace shell, equipped with mechanical pump + diffusion pump vacuum unit, the ultimate vacuum can reach 7x 10-3Pa (empty load, cold state).

- HMl adopts an HD touch screen, a built-in operating system developed by our company.

- PLC automatic control system.

- As required, inert gas can be added for fast cooling.

Vacuum Brazing Equipment Technical Parameters

| Model | Chamber Size (W*H*D) mm | Max. Temp. (℃) | Power (KW) | Voltage (V) |

|---|---|---|---|---|

| BR-QHS-223 | 200*200*300 | 1350 | 34 | 380 |

| BR-QHS-334 | 300*300*400 | 1350 | 60 | 380 |

| BR-QHS-446 | 400*400*600 | 1350 | 98 | 380 |

| BR-QHS-557 | 500*500*700 | 1350 | 132 | 380 |

| BR-QHS-669 | 600*600*900 | 1350 | 180 | 380 |

* Other size can be customized.