Split-Type Tube Furnace up to 1200°C

- 2025-09-11 23:28

- Brother Furnace

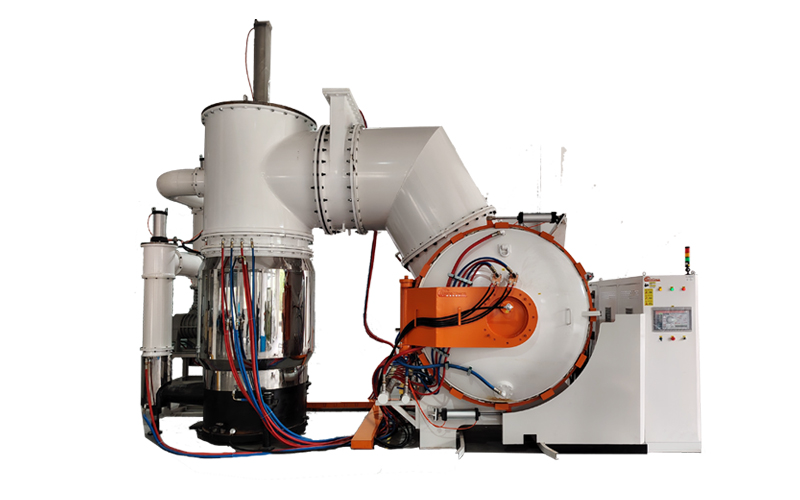

We are pleased to announce the successful dispatch of our Horizontal Split-Type Tube Furnace, designed for advanced high-temperature thermal processing applications up to 1200°C.

This high-performance furnace features a robust split-type design with a high-purity quartz tube or high-purity alumina tube as the standard furnace tube, ensuring excellent thermal stability and chemical resistance. It operates within a temperature range of 300°C to 1200°C, making it ideal for various demanding heat treatment processes.

Split-Type Tube Furnace Key Features

Precise 50-segment programmable PID temperature control system for superior automation and reproducibility.

Excellent high-temperature uniformity across the entire heating zone.

Double-layer shell with air-cooling technology, maintaining the external furnace surface below 50°C for operational safety.

304 stainless steel double-sealing flanges with an adjustable support structure to minimize mechanical stress and extend the service life of the furnace tube.

Comprehensive safety protections: over-temperature automatic shutdown and power-off in case of electrical leakage.

Fast heating rate of up to 20°C/min and exceptional temperature control accuracy of ±1°C.

Vacuum capability with a maximum vacuum level of -0.1 MPa; optional molecular pump support allows an ultimate vacuum of up to 7×10⁻⁴ Pa.

Compatible with inert gas atmospheres for oxidation-sensitive applications.

This furnace is widely used in universities, research institutes, and industrial settings for high-temperature sintering, metal material processing, quality inspection, and small-batch production.

All units are carefully packaged to ensure secure delivery and come with full operational documentation. For more technical details or support, please contact our team.

Split-Type Tube Furnace Technical Parameters

| Model | Tube Dia*Heating Zone (mm) | Power | Max. Temp (℃) | Working Temp (℃) | Thermo couple | Tube Material | Heating Elements |

|---|---|---|---|---|---|---|---|

BR-12NT-40/300 | 40*300 | 3 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-60/300 | 60*300 | 3 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-80/300 | 80*300 | 5 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-100/300 | 100*300 | 5 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-120/300 | 120*300 | 6 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-40/450 | 40*450 | 3 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-60/450 | 60*450 | 3 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-80/450 | 80*450 | 5 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-100/450 | 100*450 | 5 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

| BR-12NT-120/450 | 120*450 | 6 | 1200 | 1100 | K type | Quartz Tube | Heating wires |

*Other size can be customized.