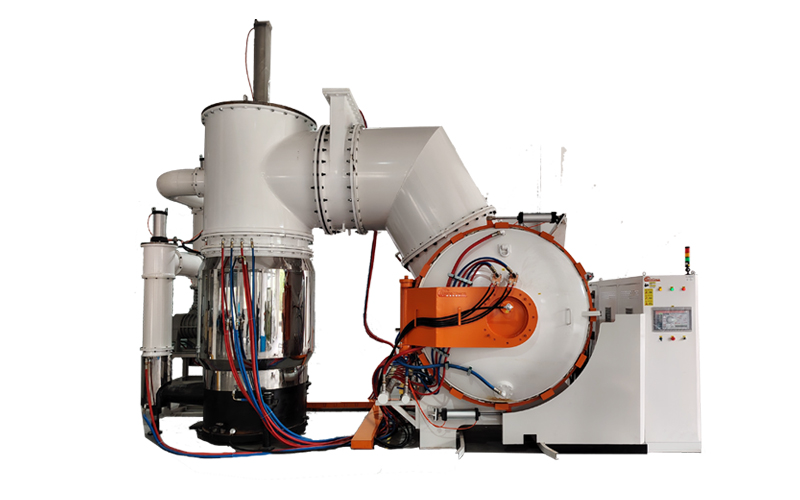

Sintering Vacuum Furnace for Powder Metallurgy

- 2025-07-31 18:34

- Brother Furnace

Our precision-engineered Sintering Vacuum Furnace for Powder Metallurgy has completed factory acceptance testing and is now prepared for immediate shipment.

This system delivers exceptional thermal uniformity at critical sintering temperatures up to 1600°C, optimized for repeatable full-density consolidation and controlled microstructure development of advanced metal, ceramic, and cermet powders. Featuring a high-integrity vacuum chamber with leak-tight sealing, it guarantees oxygen-free processing—effectively eliminating oxidation, binder residue contamination, and uncontrolled surface reactions throughout the thermal cycle.

Multi-zone heating elements ensure precise control over critical sintering parameters, enabling uniform shrinkage, predictable dimensional tolerances, and consistent mechanical properties—even for complex near-net-shape geometries. The advanced process control guarantees repeatable results for both continuous production and critical R&D sintering applications.

Sintering Vacuum Furnace for Powder Metallurgy Features

- The Chamber size: 600x600x900mm

- Max. temperature 1700 ℃

- Designed with an air inlet and exhaust port, it can be used for vacuum pumping or filling with inert gas.

- Pneumatic vacuum valve, easy to operate.

- Double water-cooling, furnace shell surface temperature≤50 ℃

- High-strength carbon steel, with an external electrostatic spray coating.

- HMl adopts an HD touch screen, a built-in operating system developed by our company.

- Programmable temperature control meter PlD adjustment.

- Upper limit alarm, deviation alarm, automatic stop at the end of program operation, no man on duty.

Sintering Vacuum Furnace for Powder Metallurgy Technical Parameters

| Model | Max. temp(℃) | Working temp | Chamber size (mm) | Heating element | Volume (L) | Power (kW) | Max. Vacuum |

|---|---|---|---|---|---|---|---|

| BR-17VF-1 | 1700 | 1600 | 100*100*100 | Mosi2 heater | 1 | 1.5 | 10Pa |

| BR-17VF-5 | 1700 | 1600 | 150*150*200 | Mosi2 heater | 4.5 | 5 | 10Pa |

| BR-17VF-12 | 1700 | 1600 | 200*200*300 | Mosi2 heater | 12 | 8 | 10Pa |

| BR-17VF-36 | 1700 | 1600 | 300*300*400 | Mosi2 heater | 36 | 12 | 10Pa |

| BR-17VF- 96 | 1700 | 1600 | 400*400* 600 | Mosi2 heater | 80 | 30 | 10Pa |

| BR-17VF-1 7 5 | 1700 | 1600 | 500*500*700 | Mosi2 heater | 175 | 45 | 10Pa |

| BR-17VF- 324 | 1700 | 1600 | 600*600*900 | Mosi2 heater | 324 | 66 | 10Pa |

| BR-17VF- 768 | 1700 | 1600 | 800*800*1200 | Mosi2 heater | 768 | 120 | 10Pa |

| Model | Max. temp(℃) | Working temp | Chamber size (mm) | Heating element | Volume (L) | Power (kW) | Max. Vacuum |

|---|---|---|---|---|---|---|---|

| BR-17HVF-1 | 1700 | 1600 | 100*100*100 | Mosi2 heater | 1 | 1.5 | 7x10-2 Pa |

| BR-17HVF-5 | 1700 | 1600 | 150*150*200 | Mosi2 heater | 4.5 | 5 | 7x10-2 Pa |

| BR-17HVF-12 | 1700 | 1600 | 200*200*300 | Mosi2 heater | 12 | 8 | 7x10-2 Pa |

| BR-17HVF-36 | 1700 | 1600 | 300*300*400 | Mosi2 heater | 36 | 12 | 7x10-2 Pa |

| BR-17HVF- 96 | 1700 | 1600 | 400*400* 600 | Mosi2 heater | 80 | 30 | 7x10-2 Pa |

| BR-17HVF-1 7 5 | 1700 | 1600 | 500*500*700 | Mosi2 heater | 175 | 45 | 7x10-2 Pa |

| BR-17HVF- 324 | 1700 | 1600 | 600*600*900 | Mosi2 heater | 324 | 66 | 7x10-2 Pa |

| BR-17HVF- 768 | 1700 | 1600 | 800*800*1200 | Mosi2 heater | 768 | 120 | 7x10-2 Pa |

* Other size can be customized.