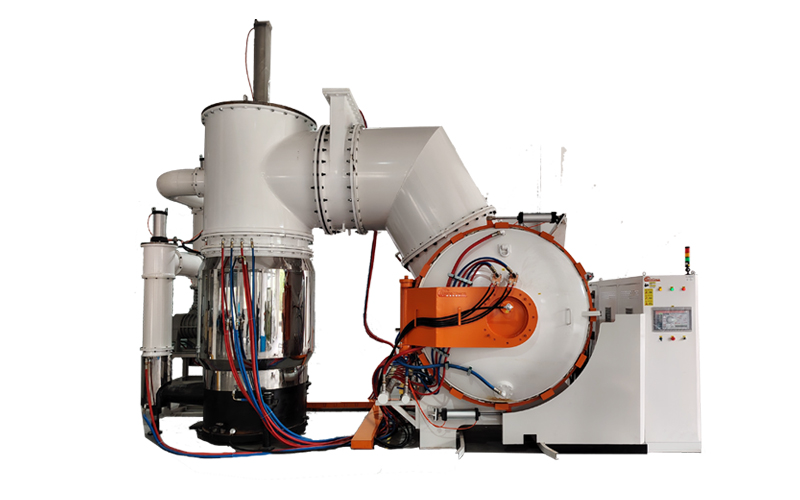

Frit Furnace for Sintering and Debinding

- 2025-07-02 01:11

- Brother Furnace

This industrial lift-type Frit Furnace is engineered for high-temperature debinding and sintering processes. Key features include:

Maximum Temperature: 1750°C

Chamber: Ceramic fiber insulation

Design: Space-saving vertical lift mechanism with bogie hearth for efficient loading/unloading

Control: Touch screen interface

Benefits: Cost-effective operation, high productivity, and ease of use.

Primary Applications

Advanced Ceramics: Sintering of Si₃N₄ (including silicon powder nitridation), AlN (including aluminum powder nitridation), Al₂O₃, SiC, and Y-TZP zirconia.

Wafer Processing: Annealing.

Powder Metallurgy: Sintering for MIM (Metal Injection Molding) and high-temperature alloys.

Energy Materials: Preparation of LiFePO₄ cathode materials.

It offers versatile high-temperature processing for diverse materials including common metals.

Frit Furnace for Sintering and Debinding standard size

| Model | Max.Temp (℃) | Chabmer size (WxHxD in mm) | Liter (L) | Power (KW) | Phase | Heater | Thermo couple |

| BR-17BL-8 | 1750 | 200*200*200 | 8 | 5 | 1 | Mosi2 heating elements | B type |

| BR-17BL-12 | 200*200*300 | 12 | 7 | 1 | |||

| BR-17BL-27 | 300*300*300 | 27 | 9 | 1 | |||

| BR-17BL-36 | 300*300*400 | 36 | 11 | 3 | |||

| BR-17BL-64 | 400*400*400 | 64 | 18 | 3 | |||

| BR-17BL-125 | 500*500*500 | 125 | 40 | 3 |

Note: Other sizes can be customized.