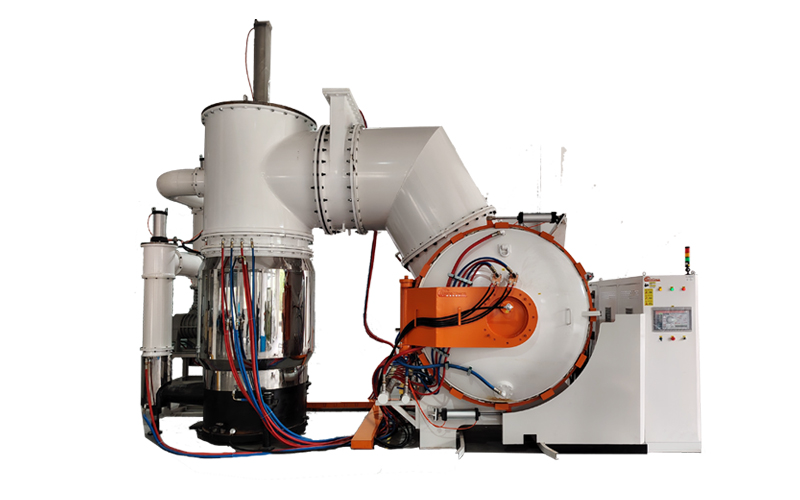

Controlled Atmosphere Induction Melting Furnace System

- 2025-07-09 01:33

- Brother Furnace

This Controlled Atmosphere Induction Melting Furnace System utilizes medium frequency induction heating within a controlled atmosphere environment. It enables metal melting under high vacuum or other protective atmospheres. Widely applicable for research and production of materials like nickel alloys, special steels, precision alloys, reactive metals, high-temperature alloys, magnetic materials, and precision casting of small parts.

Key Features

Heating: Medium frequency power supply (IGBT or KGPS). Max temperature: 2000°C.

Atmosphere: Optional high-vacuum system (Mechanical + Roots + Diffusion pumps) achieving 7×10⁻³ Pa ultimate vacuum.

Feeding: Standard alloy feeder for manual crucible charging. Optional secondary system for continuous feeding under controlled atmosphere.

Control: HMI with HD touchscreen running a proprietary operating system.

Observation: Furnace cover features a shielded observation window for process monitoring, protecting against vapor deposits.

Inductor: Internally mounted, constructed from rectangular copper tubing. Easily installed/removed via electrode coupling heads.

Crucible: Accommodates pre-sintered crucibles or allows in-situ forming. Crucible refractory material depends on the melted metal.

Controlled Atmosphere Induction Melting Furnace System Technical Parameters

| Model | Capability(KG) | Rated Frequency(HZ) | Power(KW) | Max. Vacuum (Pa) | Cooling Water (T/H) |

|---|---|---|---|---|---|

BR-RLL-10 | 10 | 3000 | 60 | 7x10-3 Pa | 10 |

BR-RLL-25 | 25 | 2500 | 120 | 7x10-3 Pa | 15 |

BR-RLL-50 | 50 | 2000 | 160 | 7x10-3 Pa | 25 |

BR-RLL-100 | 100 | 2000 | 200 | 7x10-3 Pa | 30 |

BR-RLL-200 | 200 | 1000 | 200 | 7x10-3 Pa | 35 |

BR-RLL-300 | 300 | 800 | 250 | 7x10-3 Pa | 40 |

BR-RLL-500 | 500 | 800 | 350 | 7x10-3 Pa | 50 |

BR-RLL-1000 | 1000 | 800 | 400 | 7x10-3 Pa | 70 |

* Other size can be customized.