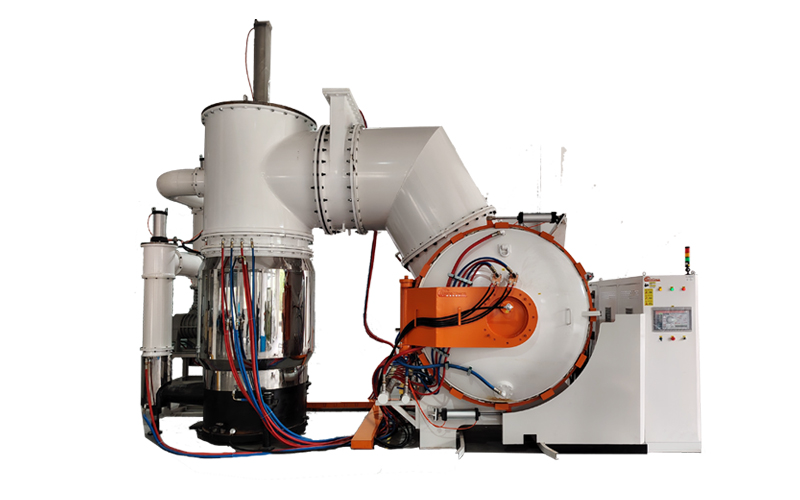

Vacuum Debinding, Degassing, and Sintering Furnace for Aluminum Alloys (6061 & 7075)

- 2026-01-09 18:54

- Brother Furnace

A vacuum furnace is the preferred and most advanced industrial solution for the integrated thermal processing of aluminum alloy components, particularly those manufactured via powder metallurgy (PM) or metal injection molding (MIM) using alloys like 6061 (Al-Mg-Si) and 7075 (Al-Zn-Mg-Cu). This single-furnace system executes a critical, multi-stage thermal cycle under a controlled vacuum atmosphere, transforming a "green" part into a high-integrity, near-fully dense final product.

The vacuum environment is the key technological differentiator. It serves three primary functions: first, it facilitates the efficient and contaminant-free removal of organic binders (thermal debinding) during the initial heating phase. Second, and most critically for aluminum, it provides an optimal medium for degassing. Aluminum powders have a high affinity for adsorbing moisture and gases, which can lead to residual porosity and embrittlement if not removed. The vacuum actively extracts these volatiles, especially hydrogen, prior to sintering. Finally, it creates an ultraclean, oxygen-free environment that prevents oxide formation—a significant barrier to sintering in aluminum—and enables superior solid-state sintering. During the high-temperature soak (typically between 570°C and 620°C, below the alloy's solidus), atomic diffusion across powder particle boundaries is enhanced, leading to pore elimination, neck growth, and consolidation.

For high-strength, precipitation-hardenable alloys such as 6061 and 7075, this controlled vacuum process is essential. It yields sintered components with high density (>98% theoretical), excellent mechanical properties, and reproducible microstructure, which can be further enhanced by subsequent aging (T6 temper). This method is distinctly superior to processes using hydrogen-containing atmospheres, which pose risks of hydrogen uptake and associated embrittlement in aluminum.

Vacuum Debinding, Degassing, and Sintering Furnace Features

Installing a square-sealed box in the furnace saves space and increases efficiency. It also prevents degreasing and volatile gases from contaminating the furnace walls and insulation by discharging them outside.Optional protective gas atmosphere ( N2, Ar). The pre-vacuum of the furnace can effectively carry out the negative pressure degreasing.

Multi-layer graphite backing plate, effective use of furnace space for loading materials.

Graphite heating elements, high-purity graphite composite carbon felt insulation.

Max. temperature: 1600°C,

Multi-zone heating

Precise temperature control

Excellent temperature uniformity

Precise temperature control

Automated process control

A vacuum environment prevents oxidation

A mechanical pump + roots pump vacuum unit can be vacuumed to 10Pa in 10 minutes.

If you have any technical questions or require assistance with your specific application, please do not hesitate to contact our engineering team.