Rotating Tube Furnace up to 1200°C

- 2025-12-30 21:47

- Brother Furnace

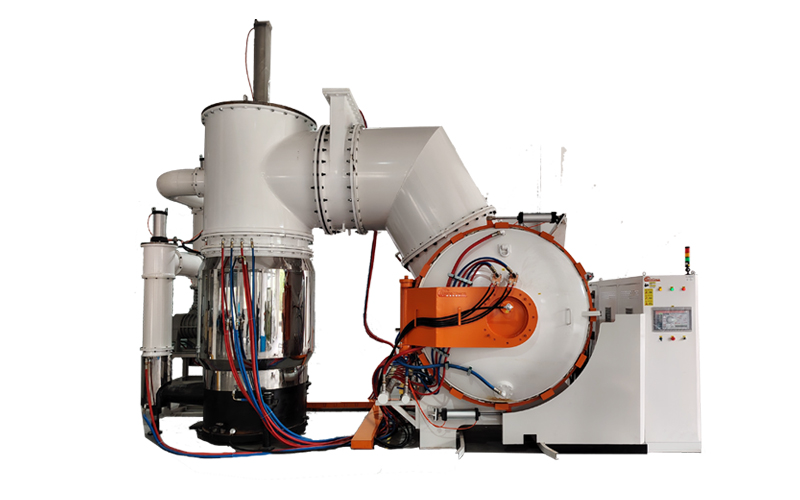

We are pleased to announce the successful dispatch of our latest Rotating Tube Furnace, engineered for sophisticated thermal processing applications requiring temperatures up to 1200°C. This shipment marks another milestone in providing advanced solutions for materials research and industrial heat treatment.

This robust Horizontal Split-Type Rotary Tube Furnace is designed to combine high-temperature performance with enhanced processing capabilities. Its key feature—a continuously rotating furnace tube—ensures superior mixing and uniform thermal exposure for powdered or granular materials, leading to more consistent and efficient reactions.

Key Specifications & Features

Maximum Operating Temperature: 1200°C

Heating Chamber Design: Horizontal, split-type for excellent accessibility and ease of loading/unloading.

Furnace Tube: Standard options include high-purity quartz tube, ensuring excellent thermal stability and chemical resistance.

Core Function: The motor-driven rotation system allows for precise control of the tube's rotational speed, facilitating optimal material agitation.

Primary Applications & Uses

This Rotating Tube Furnace is an indispensable tool for a wide range of high-temperature processes, including but not limited to:Materials Synthesis & Calcination: Uniform synthesis and calcination of advanced ceramics, catalysts, phosphors, and battery materials (e.g., cathode/anode powders).

Catalyst Research & Activation: Precise thermal activation, regeneration, and testing of heterogeneous catalysts under controlled atmospheres.

Powder Heat Treatment: Annealing, sintering, and surface modification of metallic or ceramic powders to achieve desired phase composition and properties.

Solid-State Reactions: Facilitating homogeneous solid-state reactions between powdered reactants to produce complex compounds.

Laboratory Research & Development: Serving as a versatile platform for thermal process development in fields such as metallurgy, chemistry, and nanomaterials.

This furnace is now en route to our customer, where it is expected to become a cornerstone of their thermal processing capabilities. We are confident it will deliver the precision, reliability, and performance required for their most demanding applications.

For more information on our range of tube furnaces and custom thermal solutions, please contact our technical team.